Fumex ventilation system

Design project

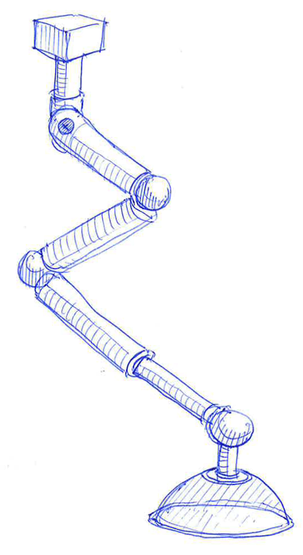

Final design.

The project

The task for this project was to interview researchers at Umeå University and to design a ventilation system that could meet their needs.

The result was presented to Fumex, a company in northern Sweden that designs and builds industrial ventilation systems.

Research

Researchers' workspaces were examined alongside interviews to determine risks and discomforts in their day-to-day work, and possible ways of preventing exposure to these.

The researchers agreed that their setup was not optimal, and that they needed a ventilation solution that could be repositioned./p>

Researcher's workspace.

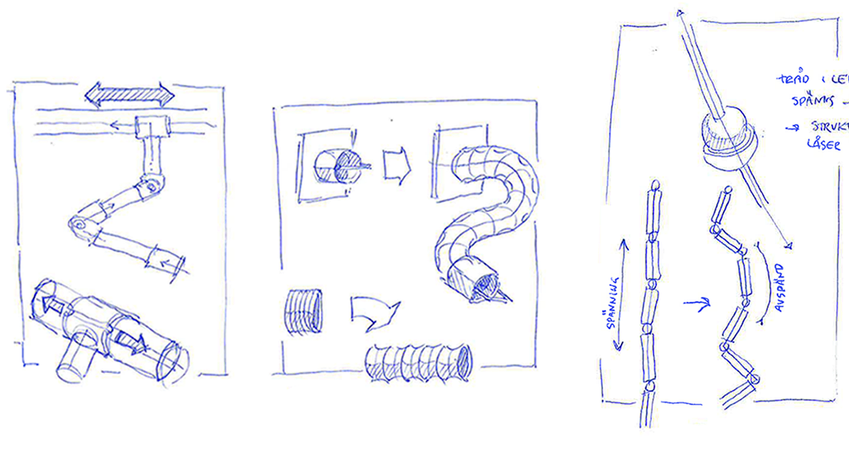

Design sketches

Ideation

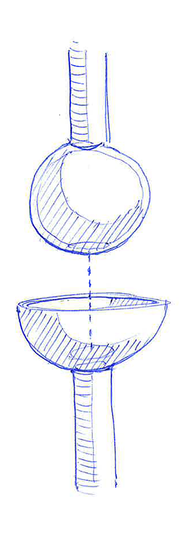

Various ideas were explored through sketching, guided by the keywords flexible, compact and maneuverable. The result was a concept involving ball sockets and a piston, which met the researchers' needs without needless complexity.

Modelling

A model was created in Solidworks to ensure the manueverability of the ventilation system. Highlighted areas indicate points where hazardous fumes are released during operation, which the fume hood needs to be able to reach to fulfill its purpose.

CAD model, demonstration of maneuvarability.

Result

The result was a fume extraction device that could be repositioned to adapt to a workspace where hazardous fumes might be released from various points during the course of work.

This solution keeps lab technicians safe and minimizes time and effort required to reposition their focused ventilation system.